"Fat girl" is the nickname of PS20 series domestic color spectrometer. It is serious about color measurement and high user satisfaction.

PS2040 "Fat girl" spectrocolorimeter is 3nh developed by CMOS dual-channel spectrocolorimeter sensor, which is not only a colorimeter, but also a spectrocolorimeter , with excellent repeatability and the inner-instrument error. The measurement data is stable, accurate and reliable. with a comfortable and round appearance more people love it. It also has quality management software facilitate quality monitoring and data management.

PS2040 color difference analyzer spectrocolorimeter is equipped with double aperture: Φ4mm /Φ5mm flat and tip, widely used for plastic electronics, paint ink, textile and garment printing, printing, ceramics and other industries color difference quality control.

Technical Advantages

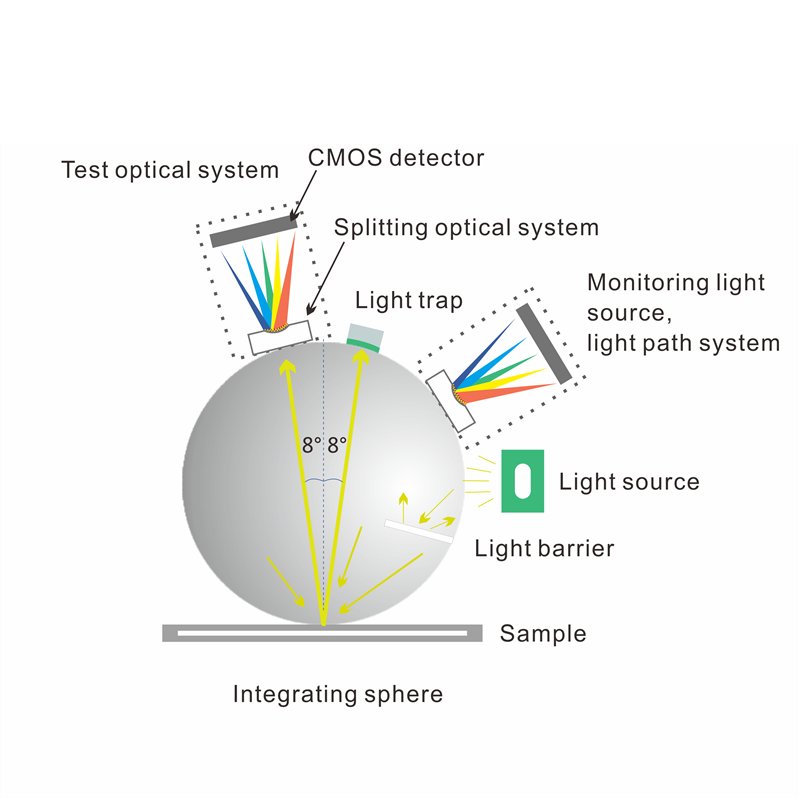

1、Adopt D/8 optical structure and SCI/SCE mode.

PS2040 spectrocolorimeter adopts D/8(diffused illumination, 8-degree viewing angle) which is widely applicable in the world, and SCI/SCE (specular component included/specular component excluded) Synthesis technology. It is suitable for color management and quality control in various industries such as color matching and coating, textile, plastic, food, building materials, cosmetics, etc.

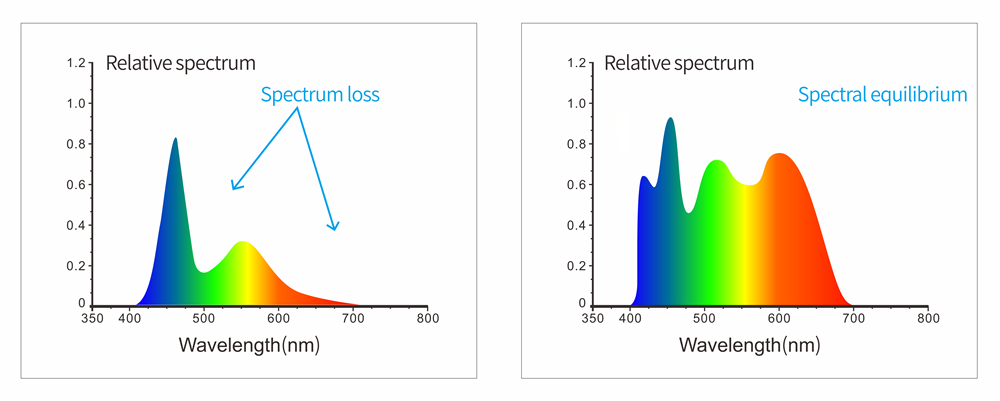

2、Adopt D/8 optical structure and SCI/SCE mode.

The 400~700nm full waveband balanced LED light source ensures sufficient spectral distribution in the visible light range, avoids the spectral loss of white LED in specific waveband, Fluorescent materials can also be easily measured and ensures the measurement speed and accuracy of the measurement results.

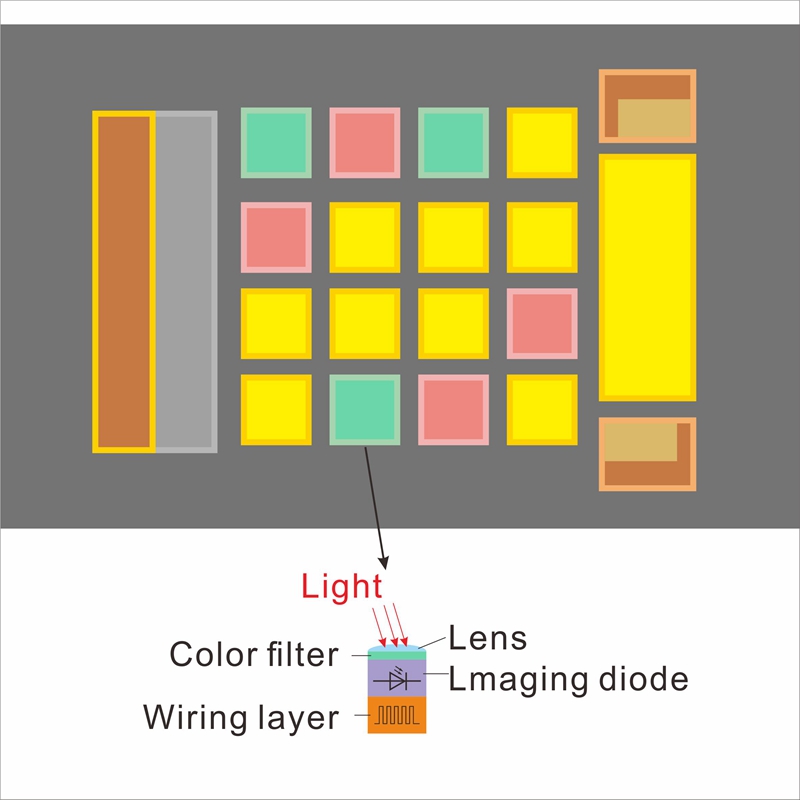

3、CMOS dual beam splitting sensor

High speed and high sensitivity CMOS dual beam splitter sensor makes color data processing more efficient and accurate.

4、Contact automatic whiteboard calibration

The spectrocolorimeter PS2040 is equipped with an intelligent calibration base.Contact automatic whiteboard calibration is available, professional standard Whiteboard reflectivity R% ≥95%, good surface uniformity It has high stability and can obtain repeated and accurate data.

5、Multiple color measurement spaces, multiple illumination source

The spectrocolorimeter PS2040 support CIE LAB, XYZ, Yxy, LCh, CIE LUV, S- RGB, βxy, DIN Lab99 Color space and D65, A, C, D50 ,D55, D75, F1, F2(CWF), F3, F4, F5, F6, F7(DLF), F8, F9, F10(TPL5), F11(TL84), F12(TL83/U30), U35, NBF, ID50, ID65 multiple illumination source,Meet different measurement requirements.

6、Ergonomic design and easy measurement

The fitted palm is suitable for continuous detection, which makes you fast and easy to use. An easy to measure device for automatic measurement is added. which is portable, fast, easy to measure and use.

7、Calibration Certificate

Each PS2040 spectrocolorimeter has been verified and tested. After leaving the factory, each instrument is verified according to the measurement standards of authoritative verification departments, and the measurement data are traceable to the National Metro technical Institute to ensure the authority of the instrument test data.

8、Color management software

SQCX quality management software with PS2040 spectrocolorimeter is suitable for quality monitoring and color data management in various industries. Data the user's color management, compare color differences, generate test reports, provide multiple color space measurement data, and customize the customer's color management.

Technical Specification

| Model | PS2040 spectrocolorimeter |

| Optical Geometry | D/8(diffused illumination, 8-degree viewing angle), SCI/SCE (specular component included/specular component excluded) Mode, Comply to CIE No.15,GB/T 3978,GB 2893,GB/T 18833,ISO7724-1,ASTM E1164,DIN5033 Teil7 |

| Characteristic | Adopt CMOS dual beam splitting sensor;Used for color difference quality control in plastic electronics, paint and ink, textile and garment printing and dyeing, printing, ceramics and other industries. |

| Light Source | Combined full spectrum LED light source |

| Integrating Sphere Size | Φ40mm |

| Sensor | CMOS dual beam splitting sensor |

| Wavelength Range | 400-700nm |

| Measuring Aperture | Two Apertures: SAV:Φ4mm/Φ5mm |

| Specular Component | SCI/SCE |

| Color Space | CIE LAB,XYZ,Yxy,LCh,CIE LUV,s-RGB,HunterLab,βxy,DIN Lab99 |

| Color Difference Formula | ΔE*ab,ΔE*uv,ΔE*94,ΔE*cmc(2:1),ΔE*cmc(1:1),ΔE*00, DINΔE99,ΔE(Hunter) |

| Other Colorimetric Index | Spectral reflectance, WI(ASTM E313,CIE/ISO,AATCC,Hunter), YI(ASTM D1925,ASTM 313),Metamerism Index Mt,Staining Fastness, Color Fastness,Color Strength, Opacity,555 tone classification, Munsell(C/2)(Partially realize through the PC software /APP software) |

| Observer Angle | 2°/10° |

| Illuminant | D65,A,C,D50,D55,D75,F1,F2(CWF),F3,F4,F5,F6,F7(DLF),F8,F9,F10(TPL5),F11(TL84),F12(TL83/U30),U35,NBF,ID50,ID65(Partially realize through the PC software /APP software) |

| Display | Spectrogram/Values, Samples Chromaticity Values, Color Difference Values/Graph, PASS/FAIL Result, Color Simulation, Color Offset |

| Measuring Time | About 1s |

| Repeatability | Chromaticity value: MAV/SCI, within ΔE*ab 0.035 (After preheating and correction, the average value of the whiteboard was measured for 30 times at an interval of 5s);Spectral reflectance: MAV/SCI, Standard deviation within 0.1% (400nm to 700nm: within 0.2%) |

| Inter-instrument Error |

MAV/SCI, Within ΔE*ab 0.35 (Average for 12 BCRA Series II color tiles) |

| Displayed Accuracy | 0.01 |

| Measured Reflectance Range | 0-200% |

| Reflectance Resolution | 0.01% |

| Measurement Mode | Single Measurement, Average Measurement(2-99times) |

| Locating Method | Stabilizer position |

| White Calibration mode | Contact type automatic calibration |

| Dimension | 94X68X188mm |

| Weight | About 410g |

| Battery | Lithium battery,3.7V,5000mAh,8000 cycles in 8 hours |

| Illuminant Life Span | More than 1.2 million measurements over 10 years |

| Screen | 2.8 inch TFT true color, Capacitive Touch Screen |

| Interface | USB |

| Data Storage | Standard 500Pcs, Sample 5000Pcs (One data is able to include SCI/SCE);PC mass storage |

| Software support | Windows |

| Language | Simplified Chinese, English, Traditional Chinese |

| Operating Environment | 0~40℃, 0~85%RH (no condensing),Altitude < 2000m |

| Storage Environment | -20~50℃, 0~85%RH (no condensing) |

| Standard Accessory | Power Adapter, USB Cable, User Guide, SQCX PC Software(Download from office website), White and Black Calibration Cavity, Protective Cover, Wrist strap, Aperture |

| Optional Accessory | USB Micro Printer, Powder Test Box |

| Notes | Technical parameters are only for reference, subject to the actual sale of the product |

1. When I received NH310/NH300 colorimeter and perform measurement, why the measured data is abnormal?

After receiving NH310/NH300, you have to perform white and black calibration manually when first starting.

2. In which condition, manual white and black calibration and auto calibration are required for NH310?

a. It’s needed to perform manual calibration for NH310 when first starting.

b. In the subsequent starting, NH310 will perform auto calibration at startup. No need to perform manual calibration.

c. Suggestion: it’s best to perform manual calibration once a week or when NH310 measured data is not accurate.

3. In which condition, manual white and black calibration for NH300 is required?

a. It’s needed to perform manual calibration for NH300 when first starting.

b. In the subsequent starting, no need to perform manual calibration.

c. Suggestion: it’s best to perform manual calibration once a week or when NH300 measured data is not accurate.

4. How to replace NH310 measuring aperture?

There are three measuring apertures for NH310: Φ8mm (standard accessory), Φ4mm (standard accessory), extended Φ8mm (optional accessory)

a. Turning on

b. Removing measuring aperture, install the needed measuring aperture.

c. Select “Settings-Aperture Setting” in main menu to select corresponding measuring aperture.

d. After selecting aperture, the instrument will display “White and Black Calibration” interface. White and black calibration must be performed.

e. Replace completed.

5. CQCS3 (Color Quality Control System) Installation

a. Before installation, please Copy CQCS3 folder to your computer and don’t remove any files in CQCS3 folder.

b. Double-click the setup.exe to install CQCS3 software.

c. Then double-click Install.bat under the CQCS3\USB_Driver file to install the driver.

d. Detailed installation information please read the "Installing Software" under CQCS3 User manual.doc.

6. How to check communication port?

a. Connect colorimeter to the PC with USB cable.

b. Turn on the colorimeter to enter main menu. Select “Comm” and press “Enter” key to start communication.

c. Right click on “My Computer” on the desktop. Click “Manage” -> “Device Manager” -> “Ports”, you can see similar display as “SCI USB2Serial (COM6)”.

d. Click “Settings->Communication Parameters” in CQCS3 software interface. Select the corresponding port in “Serial Port”.

7. After completing CQCS3 installation, how to solve the problem if it display “! USB Device” or “! SCI USB2Serial (COM6)” when checking the communication port?

a. Right click “! USB Device” or “! SCI USB2Serial (COM6)”, “Update Driver” -> “Install from a list or specific location (Advanced)” -> “Next” ->“Include this location in the search” -> “Browse”, specify USB driver file path “CQCS3\USB_Driver”, click “Next”. Then it will install successfully.

b.Detailed installation information please refers to “2.2 Installing USB Driver” in Color Quality Management System User Manual.doc.

8. Notes for First Using CQCS3 Software

a. Users must specify Standard File Name, Sample File Name and Sample Database File Name when first use.

b.Standard File is use to store standard measurement data. Sample File is used to store sample measurement data. Sample Database File is used to store the measured data exported from sample records.

9. How to solve the problem when “Connection Timeout” occurred?

a. When the colorimeter is disconnected to the PC, “Connection Timeout” will occur. At the moment, you have to check whether the USB cable is well connected the colorimeter and the PC. Then you can re-plug the USB to try out.

b. After ensuring the colorimeter is connected to the PC with USB cable, turn on the colorimeter and enter the main menu. Select “Comm” and press “Enter” key to start communication.

c. Turn off CQCS3 software, and reopen it.

10. How to solve the problem when the interface display "USB Disconnect"

a. Check whether the USB cable is connected. If not, please connect it. Check whether the connection is effective. You can re-plug the USB cable to test.

b. If the USB cable is connected well but the interface still displays "USB Disconnect", please re-start the colorimeter and enter "Menu" -"Comm"to start the communication.

c. Change the USB cable or change the USB port in you PC.

11. How to solve the problem when the colorimeter cannot be turned on in the condition of battery-powered?

a. If this phenomenon occurred, it means the battery power is not enough. You need to charge the battery.

b. When charge the battery, please insert the battery to the instrument, and plug in the adapter to charge the battery. After 5 minutes, the instrument can be turned on.

c. If the instrument still cannot be turned on after charging 5 minutes, you can pull out the adapter and re-plug in to check it. Or repeat this operation.

d. If the instrument still cannot be turned on after charging 5 minutes, you can turn off the colorimeter and turn on it again to check it. Or repeat this operation.

e. If you have tried all the methods above but the colorimeter still cannot be turned on, please change the battery.