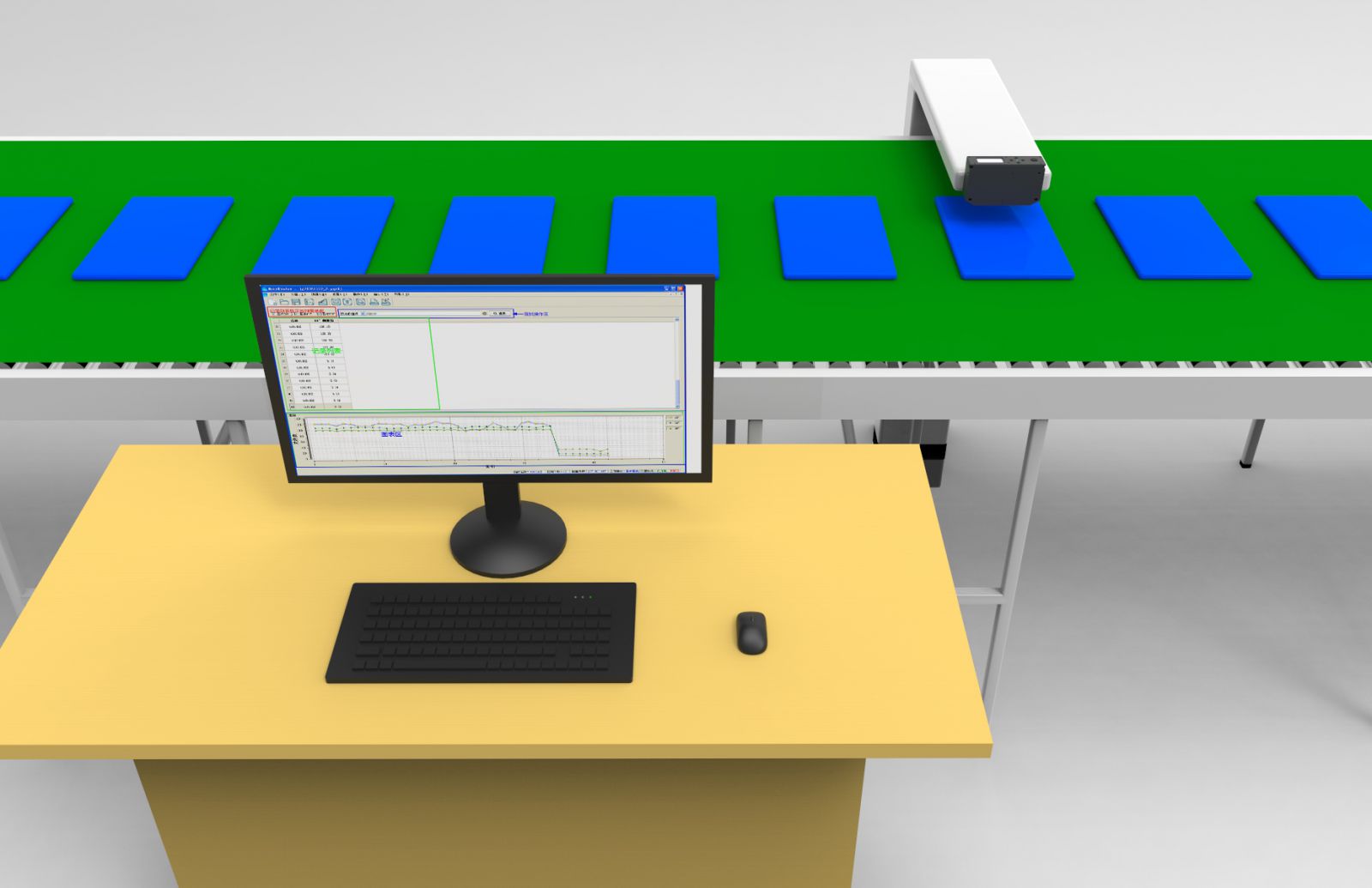

Non-contact gloss meter YG60L is an online gloss tester innovatively developed by ThreeNH. The test probe is non-contact with the sample to be tested, and it realizes non-contact testing of samples such as liquids, sauces, powders, and fragile objects. The succinct probe design allows this product to be placed anywhere in the automated production line, and can be used for online gloss measurement and quality inspection in industries such as paint, ink, coating, paper printing, plastic electronics, furniture, ceramics, electroplating, hardware, and marble . Its unique innovative design can not only provide non-contact measurement solutions directly for the production line, but also ensure stable and high-precision measurement results.

Features of Online Non-contact Gloss Meter YG60L

1、Non-contact Measurement without Damaging the Product

Accurate gloss data measurement can be achieved with a distance of 10mm from the measured plane.

2、Online real-time monitoring of product gloss

Open data interface for system integration and expansion of application scope

3、Data Stability

The repeatability of the instrument is very good, within the measurement range of 0-100GU, the repeatability can reach ±0.5GU, within the measurement range of 100-1000GU, the repeatability can reach ±0.5% of the reading

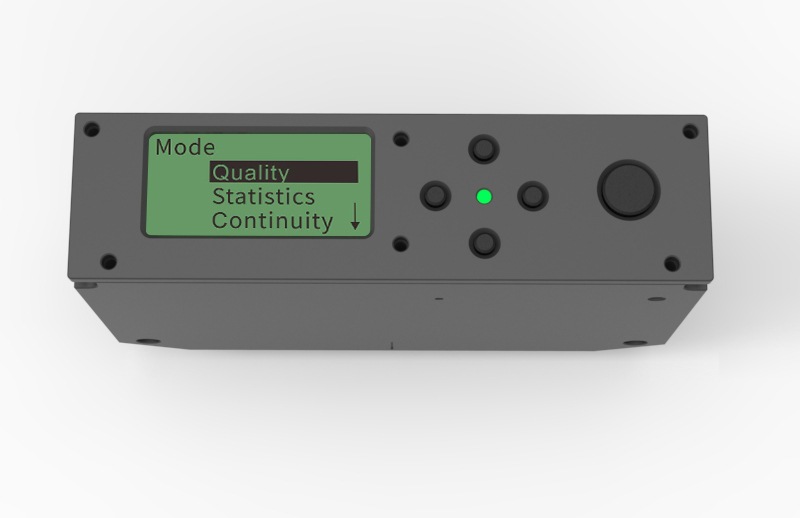

4、Multi-mode Switchable

Support basic mode, statistical mode, continuous mode, quality control mode switching, adapt to different application scenarios. The normal mode is ready to release and measure, fast reading; the quality control mode can customize the upper and lower limits to realize the rapid detection of incoming materials.

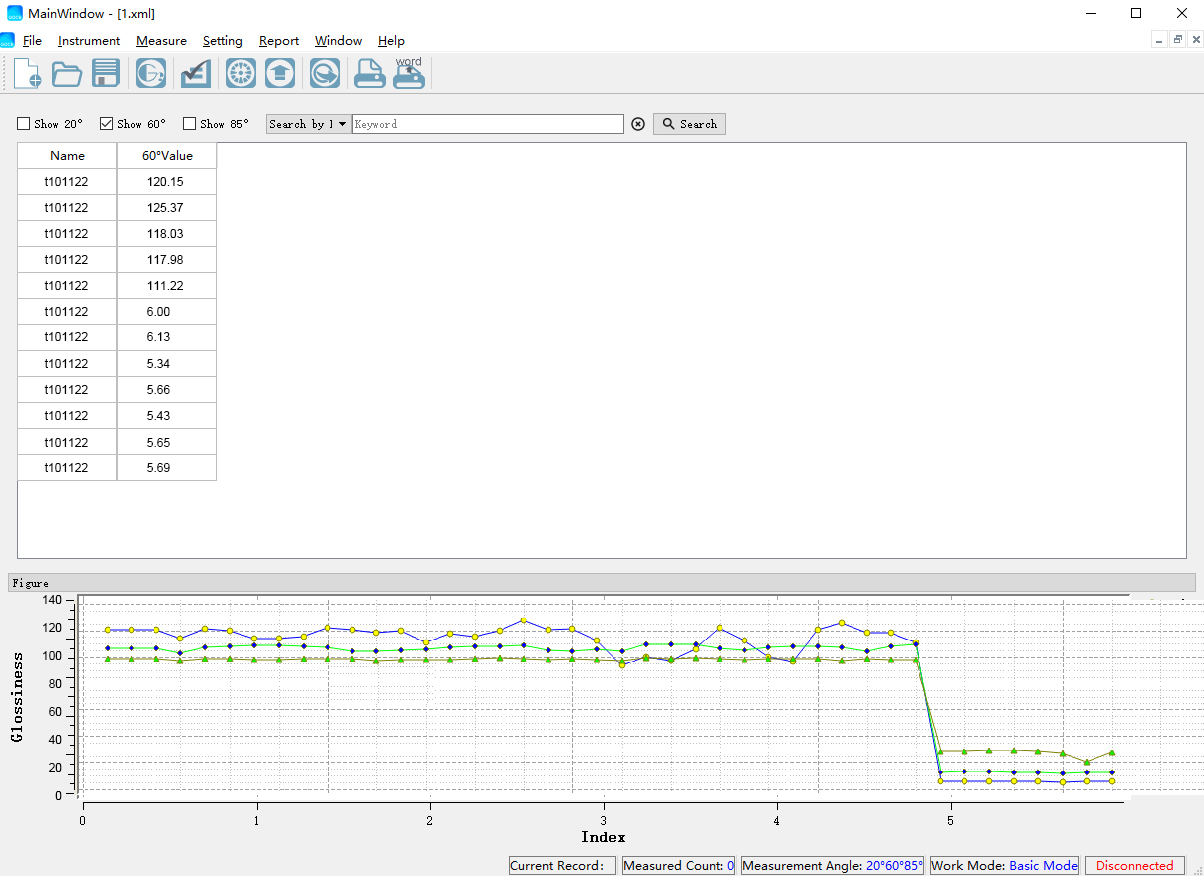

5、Powerful PC software support

The instrument is equipped with dedicated computer software (only supports Windows system), which can be connected to a computer for testing, and can generate test reports from the measured data.

Features of Online Non-contact Gloss Meter YG60L

| Product Model | YG60L Online Non-Contact Gloss Meter |

| Measuring Angle |

60°, Conform to Standards: ISO 2813、 ASTM D 523、 GB/T 9754 |

| Measuring Spot(mm) | 60°:9X15 |

| Measurement Range | 60°:0~1000GU |

| Division Value | 0.1GU |

| Non-contact Distance | Non-contact distance 10.0mm±0.1, the parallelism between the measured surface of the sample and the measuring aperture surface is 0.2 degrees |

| Features |

It can be used for gloss measurement and quality inspection in paint ink, coating, paper printing, plastic electronics, furniture, ceramics, electroplating, hardware, marble and other industries. The non-contact test between the test probe and the tested sample realizes the non-contact test of samples such as liquids, pastes, powders, and fragile objects. The measurement time can be as fast as 0.2 seconds, and it can communicate with other systems through Bluetooth or USB, and demonstrate routines of various communication interfaces. Software functions can be customized (according to the evaluation of the situation, additional customization fees will be generated). |

| Measuring Modes | Basic Mode, Statistical Mode, Continuous Mode, Quality Mode |

| Measuring Time | 0.2s/1s |

| Repeatability |

0~100GU: ±0.5GU ; 100~1000GU: ±0.5%GU Test at intervals of 5 seconds under 10mm verification tooling (ensure test distance 10 and parallelism) |

| Accuracy | Meet the requirements of JJG 696 working gloss meter |

| Auto shutdown time | 30s、60s、90s、2m or Never Shut Down |

| Long-time Calibration | With automatic calibration standard function and manual calibration |

| Language | Simplified Chinese, English, Traditional Chinese |

| Storage | 35000pcs(15,000 records in basic mode and continuous mode, 10,000 records in quality control mode, and 10,000 records in statistical mode) |

| Display | 2.3 inch black and white display |

| Dimension | 140X83X38mm |

| Weight | About 500g |

| Power Supply | Use the USB interface power adapter |

| Data Port | USB,Bluetooth 5.0 |

| PC Software | Quality inspection report printing, more function expansion |

| Operation Temperature Range | 0~40℃(32~104°F) |

| Storage Temperature Range | -20~50℃(-4~122°F) |

| Humidity | Less than 85%RH,no condensation |

| Standard Accessories | Power adapter, quality management software (official website download or after-sales), calibration standard plate, calibration bracket |

| Optional Accessories | Micro Printer |

1. When I received NH310/NH300 colorimeter and perform measurement, why the measured data is abnormal?

After receiving NH310/NH300, you have to perform white and black calibration manually when first starting.

2. In which condition, manual white and black calibration and auto calibration are required for NH310?

a. It’s needed to perform manual calibration for NH310 when first starting.

b. In the subsequent starting, NH310 will perform auto calibration at startup. No need to perform manual calibration.

c. Suggestion: it’s best to perform manual calibration once a week or when NH310 measured data is not accurate.

3. In which condition, manual white and black calibration for NH300 is required?

a. It’s needed to perform manual calibration for NH300 when first starting.

b. In the subsequent starting, no need to perform manual calibration.

c. Suggestion: it’s best to perform manual calibration once a week or when NH300 measured data is not accurate.

4. How to replace NH310 measuring aperture?

There are three measuring apertures for NH310: Φ8mm (standard accessory), Φ4mm (standard accessory), extended Φ8mm (optional accessory)

a. Turning on

b. Removing measuring aperture, install the needed measuring aperture.

c. Select “Settings-Aperture Setting” in main menu to select corresponding measuring aperture.

d. After selecting aperture, the instrument will display “White and Black Calibration” interface. White and black calibration must be performed.

e. Replace completed.

5. CQCS3 (Color Quality Control System) Installation

a. Before installation, please Copy CQCS3 folder to your computer and don’t remove any files in CQCS3 folder.

b. Double-click the setup.exe to install CQCS3 software.

c. Then double-click Install.bat under the CQCS3\USB_Driver file to install the driver.

d. Detailed installation information please read the "Installing Software" under CQCS3 User manual.doc.

6. How to check communication port?

a. Connect colorimeter to the PC with USB cable.

b. Turn on the colorimeter to enter main menu. Select “Comm” and press “Enter” key to start communication.

c. Right click on “My Computer” on the desktop. Click “Manage” -> “Device Manager” -> “Ports”, you can see similar display as “SCI USB2Serial (COM6)”.

d. Click “Settings->Communication Parameters” in CQCS3 software interface. Select the corresponding port in “Serial Port”.

7. After completing CQCS3 installation, how to solve the problem if it display “! USB Device” or “! SCI USB2Serial (COM6)” when checking the communication port?

a. Right click “! USB Device” or “! SCI USB2Serial (COM6)”, “Update Driver” -> “Install from a list or specific location (Advanced)” -> “Next” ->“Include this location in the search” -> “Browse”, specify USB driver file path “CQCS3\USB_Driver”, click “Next”. Then it will install successfully.

b.Detailed installation information please refers to “2.2 Installing USB Driver” in Color Quality Management System User Manual.doc.

8. Notes for First Using CQCS3 Software

a. Users must specify Standard File Name, Sample File Name and Sample Database File Name when first use.

b.Standard File is use to store standard measurement data. Sample File is used to store sample measurement data. Sample Database File is used to store the measured data exported from sample records.

9. How to solve the problem when “Connection Timeout” occurred?

a. When the colorimeter is disconnected to the PC, “Connection Timeout” will occur. At the moment, you have to check whether the USB cable is well connected the colorimeter and the PC. Then you can re-plug the USB to try out.

b. After ensuring the colorimeter is connected to the PC with USB cable, turn on the colorimeter and enter the main menu. Select “Comm” and press “Enter” key to start communication.

c. Turn off CQCS3 software, and reopen it.

10. How to solve the problem when the interface display "USB Disconnect"

a. Check whether the USB cable is connected. If not, please connect it. Check whether the connection is effective. You can re-plug the USB cable to test.

b. If the USB cable is connected well but the interface still displays "USB Disconnect", please re-start the colorimeter and enter "Menu" -"Comm"to start the communication.

c. Change the USB cable or change the USB port in you PC.

11. How to solve the problem when the colorimeter cannot be turned on in the condition of battery-powered?

a. If this phenomenon occurred, it means the battery power is not enough. You need to charge the battery.

b. When charge the battery, please insert the battery to the instrument, and plug in the adapter to charge the battery. After 5 minutes, the instrument can be turned on.

c. If the instrument still cannot be turned on after charging 5 minutes, you can pull out the adapter and re-plug in to check it. Or repeat this operation.

d. If the instrument still cannot be turned on after charging 5 minutes, you can turn off the colorimeter and turn on it again to check it. Or repeat this operation.

e. If you have tried all the methods above but the colorimeter still cannot be turned on, please change the battery.