MS3012 Multi-angle spectrophotometer adopts Industrial-grade MCU with

12 measuring angles, which can provide accurate and consistent color measurement

for metalllics, pearlescents and other complex special effect finished

products. The smooth operating system and superior performance of the optical

system allow the MS3012 multi-angle spectrometer to provide repeatability

and reproducibility of Sparkle Grade(SG),Diffuse coarseness(DC) and Color

Variation(CV) measurement.

3nh Multi-angle spectrophotometer MS3012 is used to measure the color

difference for the surface paint which is affected by different viewing

angles and viewing conditions. It can not only measure multi-angle color

difference, but also measure and characterize special finishes through

12 measuring angles. Even in the curved surface, it also has high measuring

accuracy and stability.

Technical characteristics

1. Multi-angle measurement

Adopt 7 illumination sources, 2 receivers to measure 12 measurement angles

at the same time

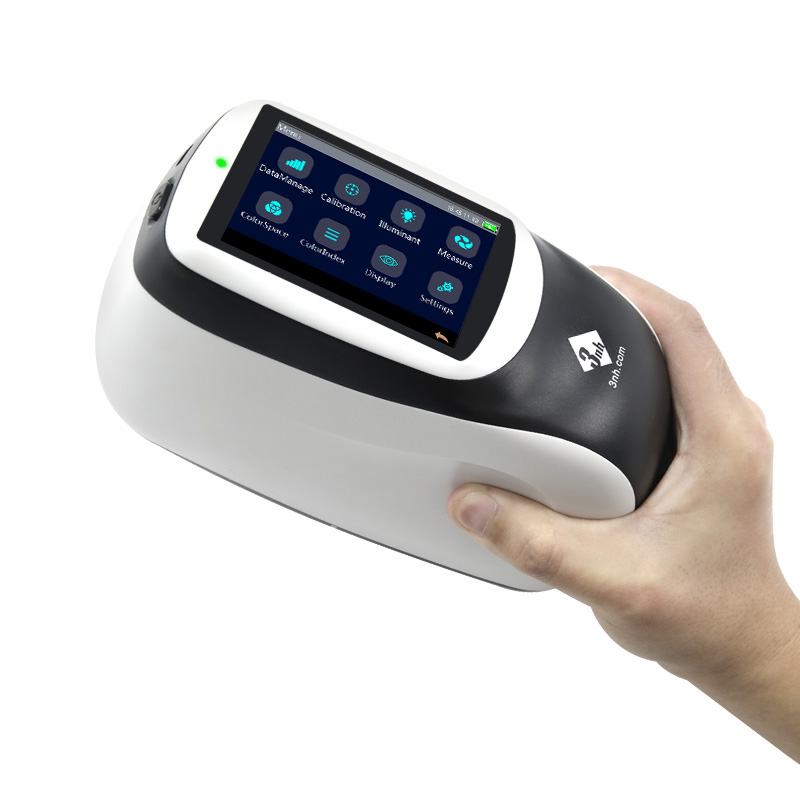

2. More intuitive display

Touch screen can display all Angle measurement results, more intuitive

view of the comprehensive data.

3. Effect measurement discrimination function

Quickly distinguish the sample Sparkle Grade(SG),Diffuse coarseness(DC)

and Color Variation(CV), simple and effective quality inspection.

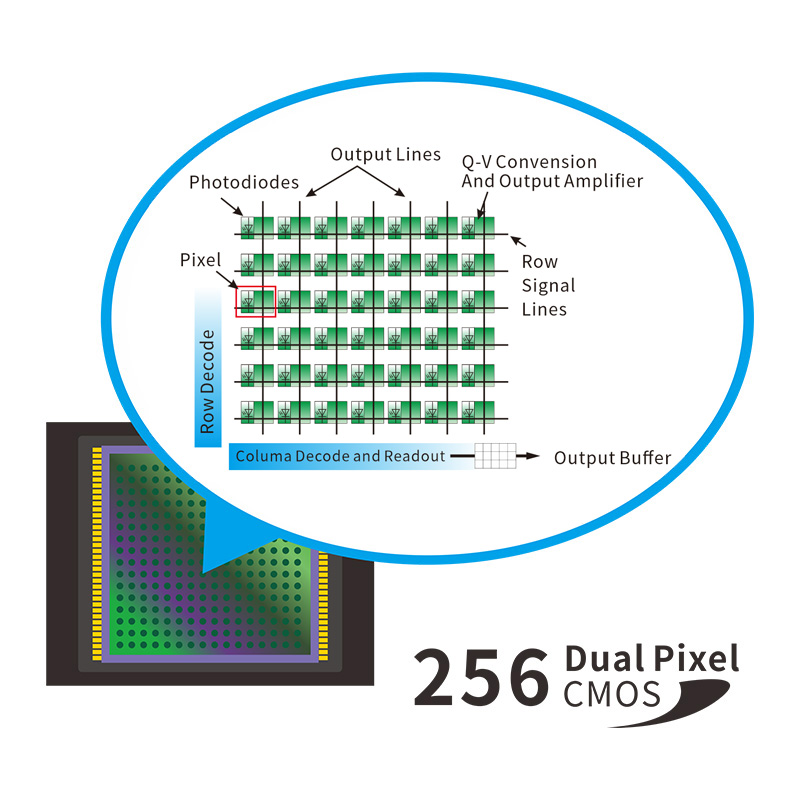

4. 256 Image Element Double Array CMOS Image Sensor

The higher optical resolution ensures the measuring speed, accuracy, stability

and consistency of the instrument. The core technology makes it as the

same platform with international standards and complete compatibility.

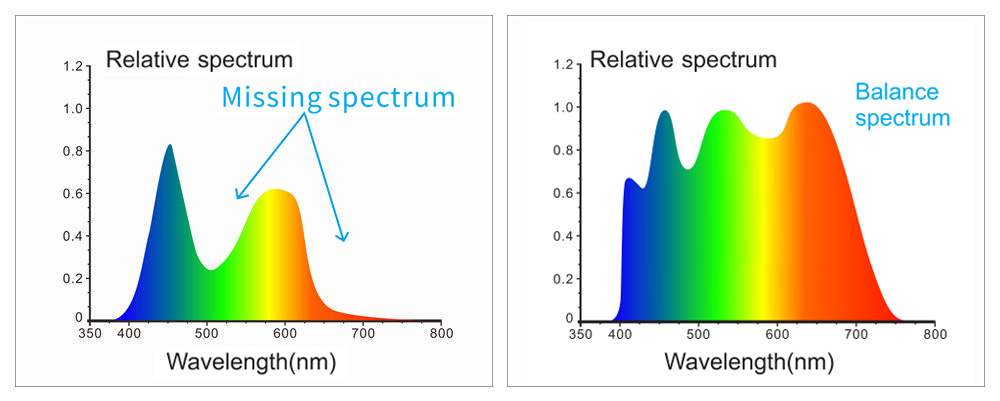

5. Adopt Full spectrum LED light source with blue enhancement

The Full spectrum LED light source with blue enhancement ensures sufficient

spectral distribution in the visible light range, avoids the spectral loss

of LED in a specific band, and ensures the accuracy of instrument measurement

results and low cost maintenance.

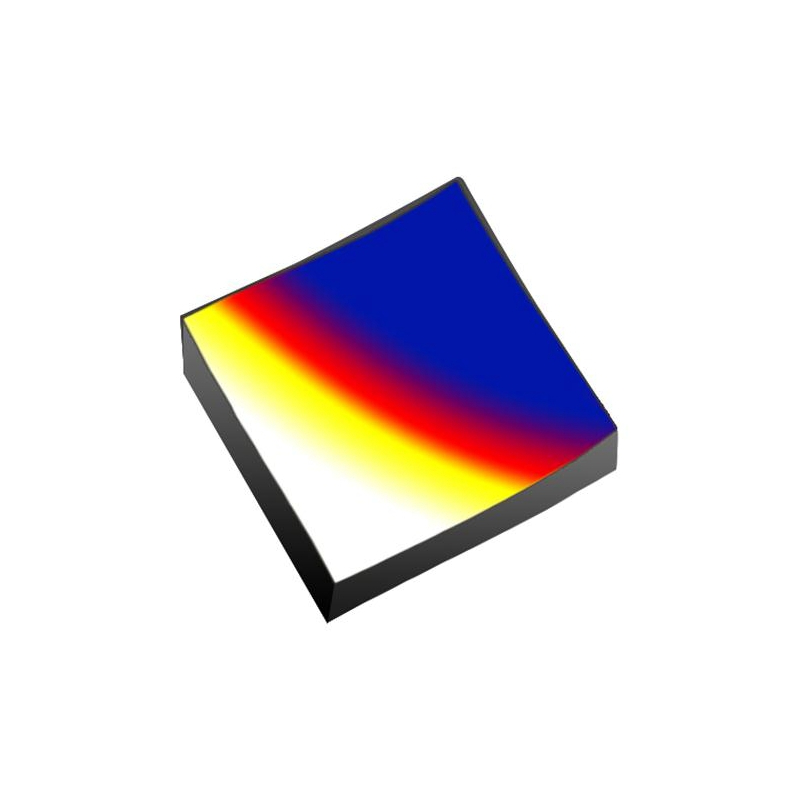

6. Concave grating spectrophotometric technology

Using concave grating spectrophotometric technology, with higher resolution,

makes color measurement more accurate.

7. Professional-grade white board

Professional-grade white board, high hardness in the surface, stable optical

performance

8. Higher quality

Industrial grade real-time processing MCU, Bluetooth 5.0 transferring

more stable and reliable.

9. Ergonomics Novel and fashionable appearance design

The instrument appearance design is easy to operate, and the hand holding

position and the measurement button are well-designed, which can meet different

holding habits, smooth and fine surface, from the high-precision appearance

treatment process.

10. Color camera preview, can clearly observe the measured area

Built-in color camera positioning, can accurately judge the object measured

position, and improve the measurement efficiency and accuracy.

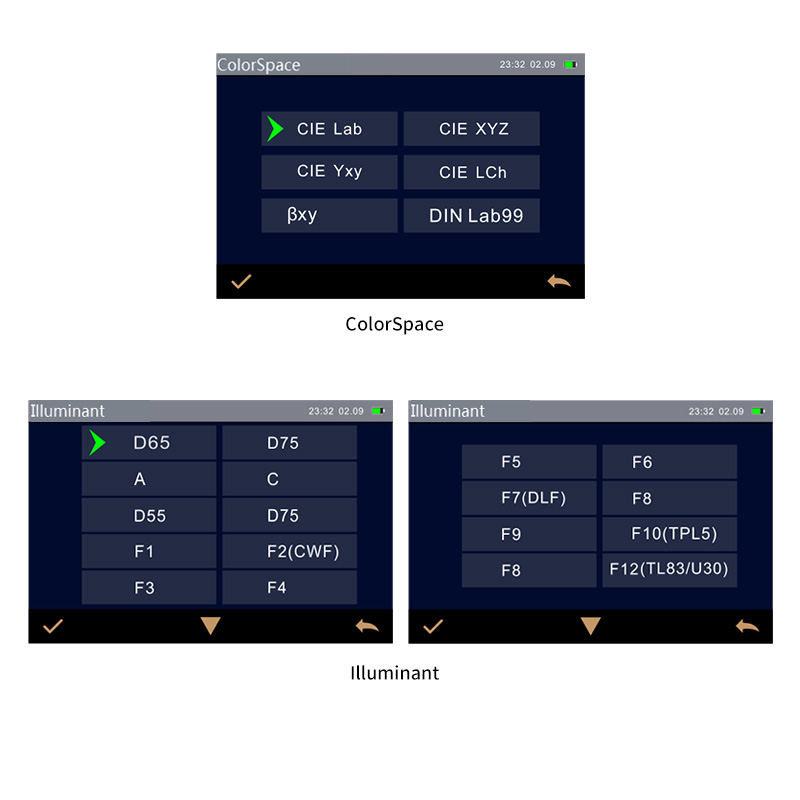

11. Multiple color measurement space, multiple observation light sources

Offer CIE LAB,XYZ,Yxy,LCh,β XY,DIN Lab99 color space, And D65, A, C, D50,

D55, D75, F1, F2 (CWF), F3, F4 and F5, F6 and F7 (DLF), F8, F9, F10 (TPL5),

and F11 (TL84), F12 (TL83/ U30) A variety of light source, which can meet

the special measurement demand under different measurement conditions.

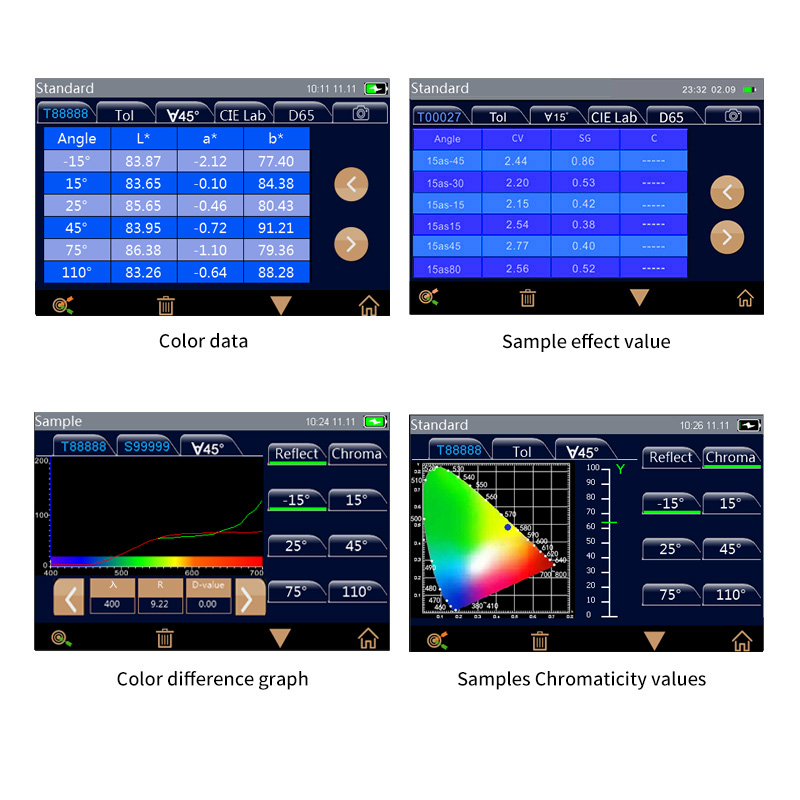

12. Easily analyze data

The screen can intuitively display spectrum/data, sample chromaticity

value, color difference value/figure, pass/fail results, color simulation,

sample effect value, effect difference value and other data, convenient

to view while also greatly improve the user's work efficiency.

Technical parameters

| Model | MS3012 |

| Measurement Geometry | 12 measurement angles (7 illumination sources, 2 receivers) |

| Measure Angle |

45° Receiver: 45as-15°,45as15°,45as25°,45as45°,45as75°,45as110° 15°Receiver: 15as-45°,15as-15°,15as15°,15as-30°,15as45°,15as80° Conform to the standards:ASTM D 2244,E 308,E 1164,E 2194, E2539,DIN 5033,5036,6174,6175-1,6175-2;ISO 7724, 11664-4 SAE J 1545 |

| Application | Provide accurate and consistent color measurement for metallic, pearlescent and other complex special effect color products |

| Light Source | Full spectrum LED light source with blue enhancement |

| Lamp Life | 5 years, 3 million times measurements |

| Spectrophotometric Mode | Concave Grating |

| Sensor | 256 Image Element Double Array CMOS Image Sensor |

| Wavelength Range | 400nm-700nm |

| Wavelength Interval | 10nm |

| Measurement Range | 0~600% |

| Semiband Width | 10nm |

| Measuring Aperture | Φ12mm |

| Color Space | CIE LAB,XYZ, Yxy,LCh,βxy,DIN Lab99 |

| Color Difference Formula | ΔE*ab,ΔE*94,ΔE*cmc(2:1), ΔE*cmc(1:1),ΔE*00, DINΔE99,ΔE DIN6175 |

| Other Colorimetric Index | Flop Index, Int-Em |

| Observer Angle | 2°/10° |

| Illuminant | D65,A,C,D50,D55,D75, F1,F2(CWF),F3,F4,F5, F6,F7(DLF),F8,F9,F10(TPL5), F11(TL84),F12(TL83/U30) |

| Display | Spectrogram/Values, Samples Chromaticity Values, Color Difference Values/Graph, PASS/FAIL Result, Color Offset, Color simulation, Sample effect value, Effect difference value |

| Measuring Time |

Approx. 1 second for one angle Approx. 12 seconds for all angles |

| Repeatability |

Spectral reflectance: Standard deviation within 0.08% Chromaticity value: ΔE*ab 0.02 ( When a white calibration plate is measured 30 times at 5 second intervals after white calibration) |

| Reproducibility |

ΔE*<0.10,avg on the gray tile of BCRA tile set ΔE*<0.25,avg on the color BCRA tile set |

| Inter-instrument Error | 0.18ΔE*00(avg on reference Series II BCRA tile set) |

| Effect Parameters | Sparkle Grade(SG),Diffuse coarseness(DC) and Color Variation(CV) |

| Effect Measurement |

6 angles Sparkle Grade(SG),Color Variation(CV):15as-45°,15as-30°,15as-15°,15as15°,15as45°,15as80° 15d Diffuse coarseness(DC) |

| Effect Repeatability |

Sparkle Grade(SG) Short-term repeatability: 0.12% (10 times standard deviations)

(When a color plate is measured 10 times at 10 second intervals after white

calibration) Diffuse coarseness(DC) Short-term repeatability:e0.09% (10 times standard deviations) (When a color plate is measured 10 times at 10 second intervals after white calibration) |

| Effect Reproducibility |

Sparkle Grade(SG) Reproducibility: 1.9% (10 times standard deviations) (avg on reference Series II BCRA tile set) Diffuse coarseness(DC) Reproducibility: 1.4% (10 times standard deviations)(avg on reference Series II BCRA tile set) |

| Trigger mode | Pressure sensing trigger, button trigger, software trigger |

| Measuring Mode | Single measurement, average measurement (1-99), continuous measurement (1-99) |

| Locating Mode | Color camera preview |

| Dimension | L*W*H=195X83X128mm |

| Weight | About 1Kg |

| Power | lithium-ion battery, 3.7V,5000mAh, Continuous test 6000 times within 8 hours of full charge |

| Display | 3.5-inch TFT color LCD, Capacitive Touch Screen |

| Interface | USB, Bluetooth 5.0 |

| Data Storage | 1000 pcs Standards,4000 pcs Samples |

| Language | Simplified Chinese, Traditional Chinese, English |

| Operating Environment | 10℃ to 50℃, humidity does not exceed 85%, no condensation |

| Storage Environment | -20℃ to 50℃, humidity does not exceed 85%, no condensation |

| Calibration | Built-in white board parameters, external white board, black light trap, color board |

| Calibration Interval | 4 hours,8 hours,24 hours,Startup calibration |

| Standard accessories | Power Adapter, USB Cable, User Guide,PC Software(download from the official website), Calibration Board, black light trap,Protective cap, wristband |

| Optional Accessory | Micro-printer |

| Notes | Technical parameters are for reference only, subject to actual sales products. |

1. When I received NH310/NH300 colorimeter and perform measurement, why the measured data is abnormal?

After receiving NH310/NH300, you have to perform white and black calibration manually when first starting.

2. In which condition, manual white and black calibration and auto calibration are required for NH310?

a. It’s needed to perform manual calibration for NH310 when first starting.

b. In the subsequent starting, NH310 will perform auto calibration at startup. No need to perform manual calibration.

c. Suggestion: it’s best to perform manual calibration once a week or when NH310 measured data is not accurate.

3. In which condition, manual white and black calibration for NH300 is required?

a. It’s needed to perform manual calibration for NH300 when first starting.

b. In the subsequent starting, no need to perform manual calibration.

c. Suggestion: it’s best to perform manual calibration once a week or when NH300 measured data is not accurate.

4. How to replace NH310 measuring aperture?

There are three measuring apertures for NH310: Φ8mm (standard accessory), Φ4mm (standard accessory), extended Φ8mm (optional accessory)

a. Turning on

b. Removing measuring aperture, install the needed measuring aperture.

c. Select “Settings-Aperture Setting” in main menu to select corresponding measuring aperture.

d. After selecting aperture, the instrument will display “White and Black Calibration” interface. White and black calibration must be performed.

e. Replace completed.

5. CQCS3 (Color Quality Control System) Installation

a. Before installation, please Copy CQCS3 folder to your computer and don’t remove any files in CQCS3 folder.

b. Double-click the setup.exe to install CQCS3 software.

c. Then double-click Install.bat under the CQCS3\USB_Driver file to install the driver.

d. Detailed installation information please read the "Installing Software" under CQCS3 User manual.doc.

6. How to check communication port?

a. Connect colorimeter to the PC with USB cable.

b. Turn on the colorimeter to enter main menu. Select “Comm” and press “Enter” key to start communication.

c. Right click on “My Computer” on the desktop. Click “Manage” -> “Device Manager” -> “Ports”, you can see similar display as “SCI USB2Serial (COM6)”.

d. Click “Settings->Communication Parameters” in CQCS3 software interface. Select the corresponding port in “Serial Port”.

7. After completing CQCS3 installation, how to solve the problem if it display “! USB Device” or “! SCI USB2Serial (COM6)” when checking the communication port?

a. Right click “! USB Device” or “! SCI USB2Serial (COM6)”, “Update Driver” -> “Install from a list or specific location (Advanced)” -> “Next” ->“Include this location in the search” -> “Browse”, specify USB driver file path “CQCS3\USB_Driver”, click “Next”. Then it will install successfully.

b.Detailed installation information please refers to “2.2 Installing USB Driver” in Color Quality Management System User Manual.doc.

8. Notes for First Using CQCS3 Software

a. Users must specify Standard File Name, Sample File Name and Sample Database File Name when first use.

b.Standard File is use to store standard measurement data. Sample File is used to store sample measurement data. Sample Database File is used to store the measured data exported from sample records.

9. How to solve the problem when “Connection Timeout” occurred?

a. When the colorimeter is disconnected to the PC, “Connection Timeout” will occur. At the moment, you have to check whether the USB cable is well connected the colorimeter and the PC. Then you can re-plug the USB to try out.

b. After ensuring the colorimeter is connected to the PC with USB cable, turn on the colorimeter and enter the main menu. Select “Comm” and press “Enter” key to start communication.

c. Turn off CQCS3 software, and reopen it.

10. How to solve the problem when the interface display "USB Disconnect"

a. Check whether the USB cable is connected. If not, please connect it. Check whether the connection is effective. You can re-plug the USB cable to test.

b. If the USB cable is connected well but the interface still displays "USB Disconnect", please re-start the colorimeter and enter "Menu" -"Comm"to start the communication.

c. Change the USB cable or change the USB port in you PC.

11. How to solve the problem when the colorimeter cannot be turned on in the condition of battery-powered?

a. If this phenomenon occurred, it means the battery power is not enough. You need to charge the battery.

b. When charge the battery, please insert the battery to the instrument, and plug in the adapter to charge the battery. After 5 minutes, the instrument can be turned on.

c. If the instrument still cannot be turned on after charging 5 minutes, you can pull out the adapter and re-plug in to check it. Or repeat this operation.

d. If the instrument still cannot be turned on after charging 5 minutes, you can turn off the colorimeter and turn on it again to check it. Or repeat this operation.

e. If you have tried all the methods above but the colorimeter still cannot be turned on, please change the battery.